Transport

Apr 25 2024

Birmingham Airport (BHX) has achieved Level 3 (optimisation) of the Airport Carbon Accreditation (ACA) scheme for a second year.

Read more

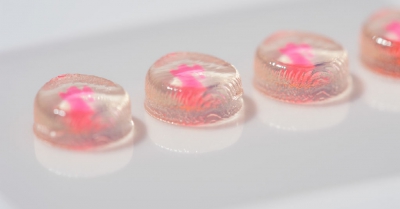

A team of researchers at the University of Nottingham are using state-of-the-art 3D print manufacturing methods to make personalised medicine a reality.

From the University’s Centre for Additive Manufacturing, Professor Ricky Wildman is leading the development of revolutionary tablets with their controlled release of prescription drugs.

Professor Wildman said:

In medicine, 3D printing has already been used to create prosthetic limbs, implants and other bespoke medical devices in a precise, effective and low-cost way. But we are exploring if this technology could be used to print personalised pills that are exactly right for each person that combines all the drugs they needed so they only had to take one a day.

Each of us have physical and biological differences that make it harder for generic medicine to be effective at a standard dose. Our age, gender and size will all have an impact, while genetic factors can also make us react differently to medicines. If you are older or have a chronic condition, for example, you may take many different tablets, several times a day, for more than one disease, but they can be difficult to swallow and to remember to take at the prescribed times. It’s a staggering fact that half the people in the UK alone don’t take their medicines correctly.

To make the technological leap, the team had to modify printers to print multiple materials at the same time and employ three different 3D printing methods to perfect the technique: inkjet; stereolithography, which uses a computer-controlled moving laser beam, pre-programmed using CAM/CAD software; and extrusion printing which uses spools of plastic or metal filament that is forced through a heated nozzle, layer by layer, to create a 3D part.

Dr. Laura Ruiz, also from the Centre for Additive Manufacturing, explains:

We have now proved that you can print pills with many types of drugs in them and release those medicines both quickly and over time. We can tailor those tablets to each individual and their specific health needs. We can design precise doses for individuals by introducing different geometries. We can also print a bespoke pill comprising layer upon layer of sections that each contain a different drug that release sequentially as required.

3D-printed pills can be manufactured wherever and whenever they are needed which reduces shipping costs and times. This revolution in the supply chain will not only save lives, by helping people in developing countries to afford better medication and reach patients in remote or challenging areas such as conflict zones, it will also cut transport emissions, making a positive impact on climate change.

Transport

Apr 25 2024

Birmingham Airport (BHX) has achieved Level 3 (optimisation) of the Airport Carbon Accreditation (ACA) scheme for a second year.

Read more

Global

Apr 24 2024

World-leading materials science and technology consultancy Lucideon is targeting international growth with expansion in the Japanese market.

Read more

Global

Apr 18 2024

The Midlands Engine Partnership will host a Pavilion for the very first time at this year’s UK Real Estate Infrastructure Investment Forum [21-23 May], providing regional partners with a platform to showcase their investment propositions, worth in excess of £42bn, to a global audience.

Read more