Researchers from the University of Warwick have successfully developed a method of wastewater treatment to remove pathogens that is not only sustainable but also able to harvest hydrogen gas capable of powering net zero transport.

The ability to treat it more sustainably was made possible once researchers from WMG, University of Warwick began using recycled carbon fibre mats to produce hydrogen from wastewater.

Treating wastewater is a vital process, as it removes pathogens and protects the environment, however, this comes at its own environmental cost as it is highly energy-intensive, using around 3% of energy use in the UK – the equivalent to 13 billion kilowatt-hours.

Severn Trent set researchers the challenge of finding a more energy-efficient way to treat wastewater, with the team successfully building on research into Microbial Electrolysis Cells.

Microbial Electrolysis Cells involves using electromagnetic microorganisms to break down organic pollutants in wastewater, producing clean water and hydrogen gas.

The ability to produce hydrogen gas is valuable as it can be sold to the chemical and plastics industry, or for use in hydrogen fuel cells for energy storage or electric vehicles.

Although promising the process has yet to be developed on an industrial scale as the materials used are made of graphite or carbon, costing several hundred pounds per square metre and producing low amounts of hydrogen.

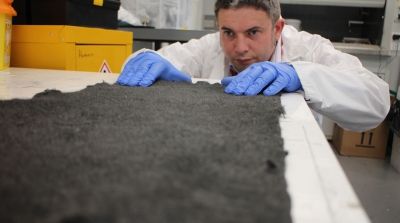

The University of Warwick team refined the technique by looking at alternative anode materials and processing methods, successfully identifying recycled carbon fibre mats as an alternative anode, which cost only £2 per square metre, making them a significantly cheaper alternative.

After testing the carbon fibre mats on synthetic wastewater and real wastewater, researchers found the bacteria developed on the recycled carbon fibre anode produced more hydrogen than previously used materials.

They then decided to pilot their techniques at Severn Trent’s Minworth waste treatment site, where they successfully processed up to 100 litres of wastewater per day and managed to remove 51% of organic pollutants and up to 100% of suspended solids from the water while producing 18 times more hydrogen (at 100% purity) than the graphite material.

Dr Stuart Coles, from WMG, University of Warwick who led the team said:

We are really excited about this technology. By taking waste from the automotive and aerospace sectors, we have developed a circular solution to a longstanding problem.

Instead of just treating the wastewater, we are now able to extract value from it in the form of hydrogen at a lower cost than ever before.

The next phase of this work is look at optimising the design of the microbial electrolysis cells and further reduce the level of pollutants in the water. This should help produce even more hydrogen!

Bob Stear, Chief Engineer at Severn Trent said:

The performance boost and cost savings demonstrated from this research mean that MEC technology is one step closer to being cost-competitive with existing wastewater treatment assets.

WMG have also demonstrated that this technology has the potential to create a more circular wastewater treatment process which will be essential to delivering on our long term sustainability goals and Net Zero plans. We’re currently scoping scaling up the technology at our test-bed plant in Redditch.

For the latest from our region, subscribe to Midlands Matters, the official newsletter of the Midlands Engine.